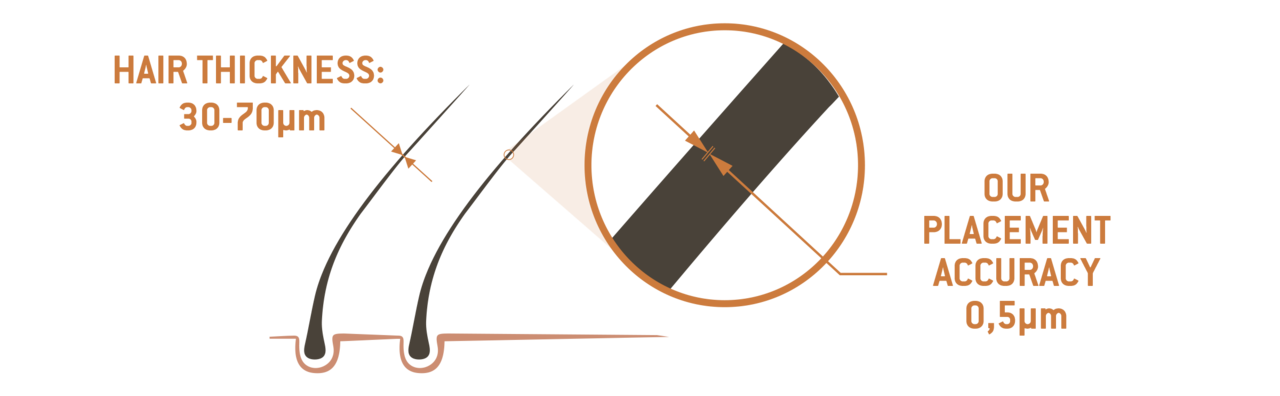

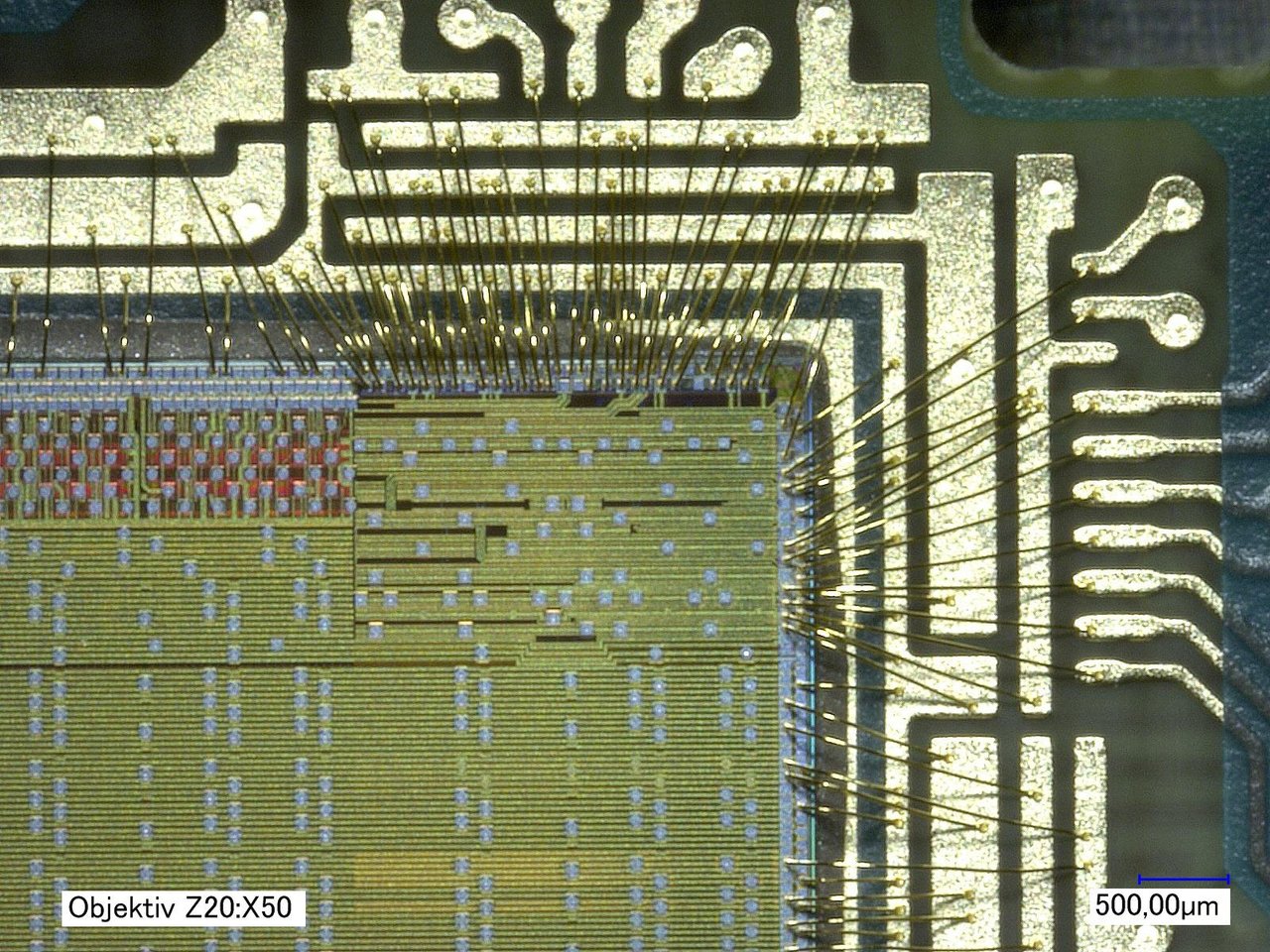

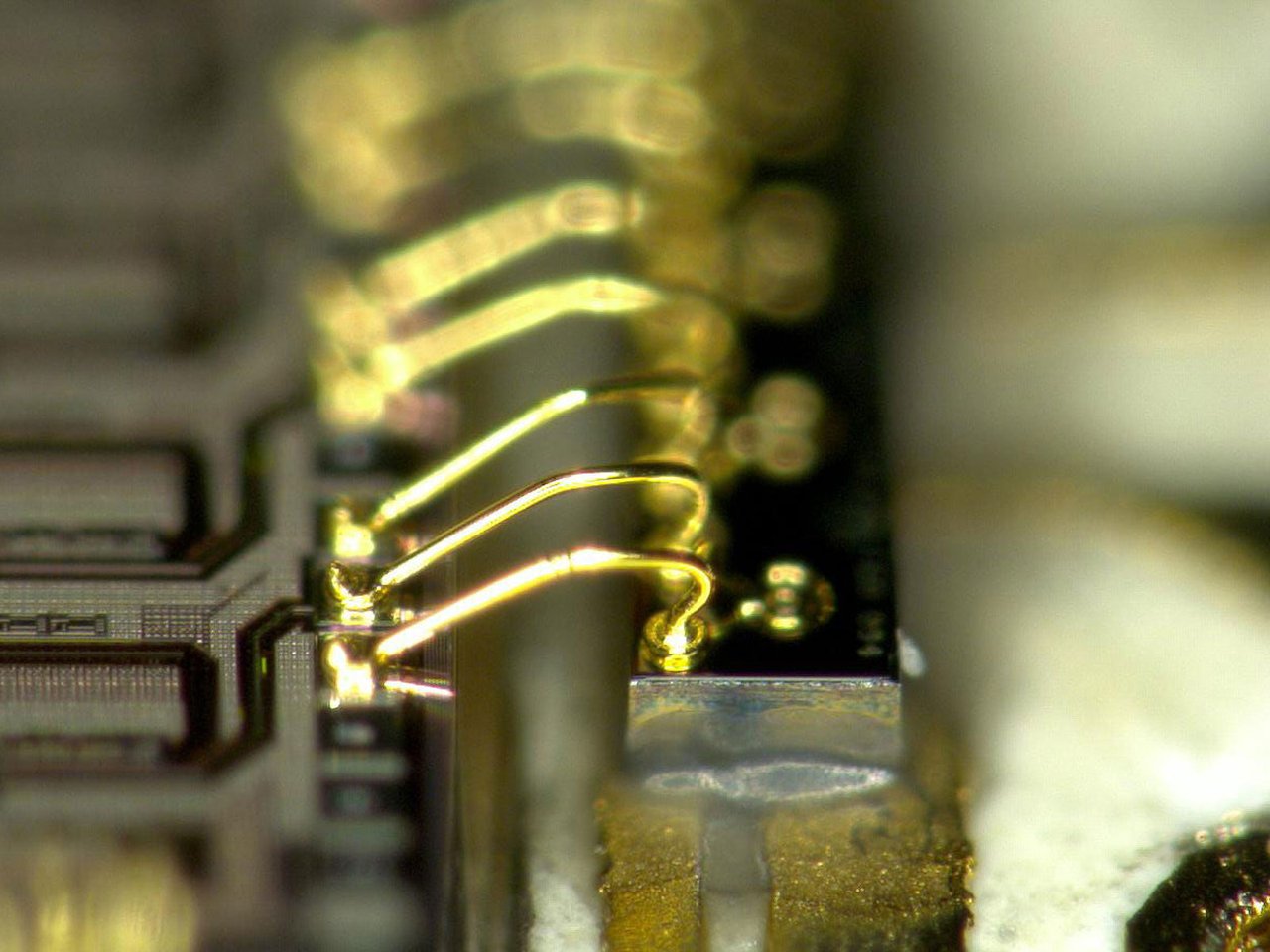

Optical components such as laser diodes or pin diodes require highly sensitive handling. Precise and meticulous assembly is a necessity to ensure functional reliability. AEMtec uses high-precision die bonders that ensure placement precision of up to 0.5µm in XY. A twist angle of 3.5 µrad or 0.0002" is also achieved.

These high-precision die bonders are placed in a clean room environment in accordance with ISO class 5.

AEMtec works with a combination of visual alignment and image recognition. Beam splitters and calibrated optics are used to simultaneously scan and visualise the surfaces of substrates with just one camera system. The versatile and reliable image recognition controls the alignment of the join partners, which is achieved by means of highly accurate manipulation of the work surface relative to the fixed tool.